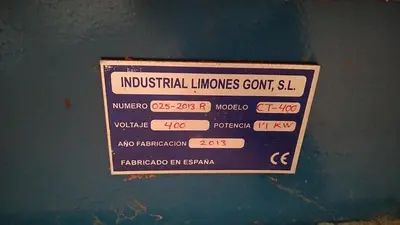

Used Industrial Limones model RD-400 Biomass Processing Plant. New in 2013.

Biomass Plant used to process and transform biomass (fuel) into energy that is used in dryer and greenhouse processes.

System composed of: Biomass storage and preparation, Hopper, Transport line in metallic structure, Sieve cylinder, Biomass input hopper for Drying Tromel, Smoke air extraction chimney, Micronized Biomass reception hopper, Biomass input from the Venturi feed to the Plant.

Biomass combustion installation in a dryer, consisting of a 2.9 MWt metal oven lined internally with refractory bricks with two medium pressure centrifugal fans for cooling driven by 7.5 hp and 4 hp engines, a biomass storage hopper of 5 Tm capacity, a collector junction between the biomass furnace and the 1 meter diameter bricks in carbon steel sheet insulated with fiberglass with decanter chimney, a particle cyclone separator made of refractory steel sheet covered with calor fiber resistant with alveolar closing valve driven by a 2 hp direct reducer, stainless steel piping diameter of 1200 mm, including union and isolation elements, electrical installation and control box. Biomass combustion installation in furnaces, consisting of two metallic biomass hoppers with a capacity of 1.5 tons of fuel, with endless feeders and pneumatic biomass conveyors between the tolvin and burner distributor composed of high pressure centrifugal fans.

Biomass combustion systems in a furnace consisting of conical rotating fuel distributors with burner outlets with neoprene collector for a working temperature of 260ºC and a thermal power of 30 kWt, electrical installation and control panel.

We use cookies to improve your experience. Privacy Policy.