Used beer brewery system (block brewery) with total volume 550 litre and nominal volume 500 litre. Brewery is designed as a block connected to stainless steel frame and steps. Unit is consist of:

1. Stainless steel vessel - lauter tun with level meter. Vessel is equipped with stirer with the possibility of changing the rpm via a frequency converter. The height of the stirrer is adjustable.

2. Stainless steel vessel - mash tun which is also used as a whirpool tank. Vessel is equipped with a tangential nozzle for filling the wort, as well as a jacket for possible pre-cooling of the wort (waste heat can be used to heat water, the jacket can be connected to a heating system up to 1.5 bar). The tank is equipped with a stirrer with the possibility of changing the speed via a frequency converter. The height of the stirrer is adjustable.

3. Alfa-Laval pump, which is controlled by a frequency converter.

4. Alfa-Laval two-stage cooler designed to cool 500 l of wort from 99 ° C to 12 ° C per hour.

5. Pipes for steam extraction, chimneys with shut-off valves.

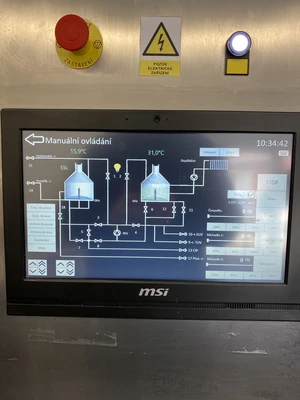

6. Control is possible in manual or semi-automatic mode via the touch screen (in the case of adding recipes, it is possible to use fully automatic control for mashing). The brewery control application can be installed in a portable device (eg a tablet) and the control can be performed by remote access.

The brewery can be connected to the following media: El. power consumption min. 20 kW, hot water 1 ", cold water 1", compressed air min. 5 Bar, neck for CIP DN40, combustion DN40. The brewery includes a measuring instrument verified by the Czech Metrology Institute with the necessary certification verification.

We use cookies to improve your experience. Privacy Policy.